|

Step 1, gut the

existing unit. Spheres and centre section have been set aside, the old

electronics have been stripped out and sold as spares. Next thing, remove the old

solenoid and fit the new one. The way I did it:

- Undo the compression fittings on the old

solenoid.

- Undo the mounting bracket from the

chassis.

- Remove the solenoid from the mounting

bracket.

- Remove the Swagelok/NPT adapters and clean

off the old tape.

- Tape the fittings and fit in the new

solenoid.

- Fit the new solenoid in the mounting

bracket.

- Fit the solenoid in place, hand tightening

the Swagelok fittings.

- Screw the bracket in place.

- Fully tighten the Swagelok

fittings.

Although the solenoid bracket is also one of

the fixing points for the centre section you don't need to remove the

centre section. I only did it because I'd let the unit sit just a little

too long in the warm weather and the inside tasted... Well, it tasted. It

shouldn't taste of anything so the time had come to Virkon everything.

Lesson learned. Handling the centre section with the lung attached has to

be one of the most terrifying experiences in working on a

Mk15. |

|

Next step, refit all this crap back into the

chassis! |

|

The

centre section has been replaced just to get it out of the way. Did I

mention I don't like handling it? Fitting a thin, irreplaceable rubber

membrane past those stainless lugs is about 8.6 on the sphincter

scale.

With the solenoid in place you can now fit the new pod.

Unlike the old pod, the HH pod is just a junction box. You don't need

access to it, everything is powered and controlled from the handset.

Simply drop it in place of the old pod, fit the stainless bracket and

screw the whole thing down. The HH pod is actually slightly smaller than

an original pod so it rattles a little in the bracket. A wrap or two of

rubber tape round it may happen in the future.

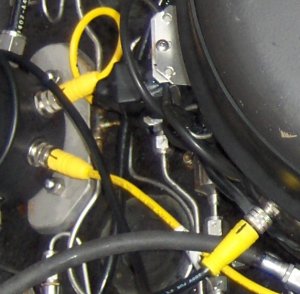

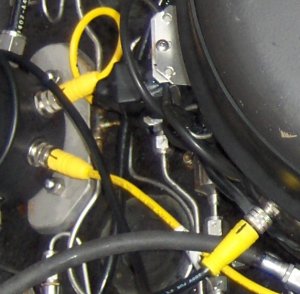

Juergensen Marine

take your old Bendix cable and splice it into the new pod so once the pod

is fitted all you have to do is connect it to your centre section with the

original plug and socket. After that, hook the solenoid to the pod with

the Lumberg fitting provided (yellow cable in the picture).

|

|

With the pod fitted and the centre section connected

then it's time to fit the DIVA. This is a nifty little HUD unit with two

modes. It will either flash to tell you if you are at setpoint or not or

it will flash a light sequence at you to tell you the actual setpoint.

Either mode is selectable from the handset. I've got mine on the

green/good, red/bad mode as it is similar to how the original primary

worked. An added feature is the DIVA has a vibrating alarm for situations

that need serious attention. As it is fitted to your DSV then the unit

rattles your teeth so, in theory, should make you pretty

aware.

Also connected is the very

nice Sartek secondary. Carl at Sartek replaced the old Bendix secondary

port on my centre section

with a Lumberg. His secondary is not dissimilar to

how the KISS and various homebuilt displays work: circuit board, panel meter,

trim pot to calibrate and a battery. A very simple digital alternative to

the old analogue secondary. The secondary came on a long cable and the excess

was taken up by a couple of wraps round the pod. |

|

I always hated trying to

fit the Bendix plugs as they were a pain to get aligned. On the Lumbergs

I've marked a black line just to make life easier. I've never claimed to

be clever and anything that makes life simple helps! |

|

I use R22DHO cells on my

Mk15 rather than the D10's. These are the same shape as R22D's as used in

the KISS and Inspiration and unfortunately are too big to fit in the

sensor ports. They need to have the tip of the cell removed precisely... I

do mine by tying them down and chopping them with a Chinese meat cleaver,

one crack and the tip is gone.

Normally they go cell face pointed

to the centre of the sensor holder but they are narrower than the port so

need either packed out with some o-rings or left to rattle. I don't like

either so, inspired by the Laguna Research sensor holder, I modified

mine. OK, it's nothing impressive, I just removed the rubber grommets for

holding the D10 sensors in place to give me a bigger hole. |

|

The cells are then

fitted sideways and fit perfectly. In fact, it is a nice, tight fit, the

cells do not move at all once in place. The assembly is finished off by

some rubber inner tubing just to hold everything in place. On the surface

they seem to work fine in this orientation and I'll see how they go

underwater. |

|

Here are the cells in

place with the scrubber fitted. Before there was just enough room to get

the scrubber on and quite a few times I'd clipped the top of a cells or a

wire and pulled a banana plug out of the board. As can be seen from the

photo, there is now a lot of clearance between the cells and the inside of

the scrubber. They could even be fitted with molexes now if I needed to

replace a cell and didn't have the chance to solder the wires

on. |

|

This is my "reassure

Dave Sutton" picture. When I bought the unit, Dave was quite concerned

that the top spider was (a) not the right one (it was a bottom spider) and

(b) slightly damaged, so would not retain the top pad properly. Dave

recommended getting someone to weld something up from stainless wire but

being a homebuilder at heart my solution was to cut a spider from the side

of an old sofnalime keg and use it to retain the wire spider. Similarity

to a Nazca spider is entirely coincidental and due to my incompetence with

a pair of shears. |

|

The unit with the

spheres in place. The oxygen regulator is original and still retains the

stainless hoses. On the diluent side I needed spare ports for my wing and

offboard connection so I had to go with another regulator. A lot of people

have used Poseidon 1st stages so so have I. The long hose is the

connection to the BOV which is in turn connected to my offboard by a

QC.

I am not entirely happy with the set up, not least because I've

lost the stainless hose advantage. I do have the option of adding offboard

to the loop via the BOV so I am planning to go back to stainless hoses and

no offboard connection. |

|

Here is the unit with

the case fitted. The unit came without the standard latchess on the side

and is instead secured by a velcro strap at the bottom. I have to say this

is a very secure modification. I have seen more than a few YBOD owners

come back on the boat with their latches popped or the shell loose. The

velcro strap has yet to let me down. |

|

Here is my hi-tech argon

strap mounting: a couple of loops of inner tube threaded through a couple

of stainless D's. |

|

Finally, the BOV and

loop hoses are fitted. The BOV is a Golem model which is well made. I

prefer it to my old Jetsam unit, it breathes better, feels better in the

mouth and the OC bailout switch is very smooth. I always found the Jetsam

version a bit clumsy and a bit big, the Golem BOV has the 2nd stage on the

bottom and the switch on the front.

The DIVA has been fixed in

place with a piece of inner tube looped round it. It was the simplest

(i.e. cheapest) option I could find and seems secure enough. Again, it

needs to be seen in the water to see if it all works.

Also visible

is the Enrique Alvarez split backplate, not overly comfortable on the

surface but very comfortable and very secure underwater. The wing is an

old Zeagle I had knocking around. I made some reinforced eyes in the

cordura bag at the top of the wing to fit the top plate, at the bottom I

extended the existing straps and made them into loops which I threaded

around the bottom plate. It works well and has the added benefit of not

having a favbric centre panel so the perforated counterlung plate is

completely open to the water. How important is that when it is sat on top

of the back of your drysuit anyway? I don't know, it can't hurt

though. |